GE Aerospace fuels expert: SAF is here to stay

Review various roadmaps for the aviation industry to reach a target of net zero CO2 emissions by 2050, and you’ll find one thing in common: Sustainable Aviation Fuel (SAF) is a linchpin for getting there.

Today, SAF production is about 0.1% of jet fuel consumed worldwide. At the recent Sustainable Aviation Futures North America conference in Houston, Texas, discussion was driven by the financial, feedstock, logistical, and other barriers to overcome to send SAF production and availability higher … much higher.

Despite the current low volumes, speaker Gurhan Andac, GE Aerospace engineering fuels and fuel additives leader, points out that SAF is here to stay.

Earlier this year, standards-setting organization ASTM International approved an eighth way to make SAF blended with conventional jet fuel, with more production process pathways in review. Over 500,000 flights have used SAF blends since 2011, according to an industry tracker. Additionally, ground and flight tests have taken place globally to inform efforts underway for development of a new standard for 100% or unblended SAF.

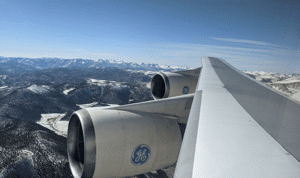

GE Aerospace has been involved with SAF for more than 15 years, since efforts to test synthetic fuel began, Andac explained. All GE Aerospace engines can operate with approved SAF blends today. That’s because approved SAF blends are drop-in, meeting specifications of Jet A and Jet A-1 and requiring no modifications to aircraft and engine equipment or infrastructure to use it.

“SAF is not an R&D project we conduct on the side. It’s in the field. We have over half a million flights in the aviation industry. Granted, these are at very low volumes, but it’s out there and we’re flying,” Andac said.

GE Aerospace’s long history of SAF testing in collaboration with industry partners includes the first commercial demonstration flight of biofuel in 2008, the first commercial aircraft flight with 100% SAF in 2018, SAF engine emissions testing, and the first passenger experimental flight in 2021 with 100% SAF in one of the two engines.

“We’ve been very active,” Andac said.

Interplay of fuels and propulsion technologies

In addition to helping advance SAF in the aviation industry, GE Aerospace is also developing new aircraft engine technologies that are more fuel efficient than today’s engines. CFM International, a 50-50 joint company between GE and Safran Aircraft Engines, is progressing on its Revolutionary Innovation for Sustainable Engines (RISE) program, the most comprehensive suite of technology development in company history with more than 1,000 GE and Safran engineers working the program worldwide.

“The CFM RISE program—this is really our answer for the next generation of technologies,” said Jeff Shaknaitis, GE Aerospace customer sustainability leader, who also spoke at the October Sustainable Aviation Future North America event.

“There’s really a couple of key markers,” Shaknaitis said. “Keep delivering more efficient propulsion technologies, helping reduce the primary energy demand from aviation. Second is making sure we’re accessing the right energy vectors that are going to be available to us, recognizing we don’t have control over the energy transition.”

Open fan engine architecture, hybrid electric systems and other technologies being matured as part of the RISE program are compatible with existing jet fuels and 100% SAF.

“We want to make sure we have technologies that are flexible to adapt over time,” Shaknaitis said.

SAF reduces lifecycle CO2 emissions

SAF has the same chemical composition as the jet fuel most commonly used today. The key difference is instead of being made from fossil-based sources, SAF is made from partially or completely renewable sources. The use of renewable feedstocks and processes reduces net CO2 emissions over the fuel’s entire lifecycle.

What’s 100% SAF?

SAF is currently approved for use in blends up to 50% with conventional jet fuel. Efforts are underway to standardize 100% drop-in SAF, which doesn’t require blending and is compatible with existing aircraft and infrastructure.

Comments