IRPC Americas ONLINE: Refinery-Petrochemical integration – Upgrading existing refineries to maximize chemicals

By Sumedha Sharma, Technical Editor, Hydrocarbon Processing

Raj Singh, Senior FCC technologist, TechnipFMC, presented a highly informative technical session on Refinery-Petrochemical integration - Upgrading existing refineries to maximize chemicals at Hydrocarbon Processing’s IRPC Americas ONLINE event today.

Mr. Singh opened his presentation discussing current market trends, industry outlook, and future demand projections for gasoline vs. petrochemicals such as propylene. He presented market data showing the shifting production emphasis towards propylene, fueled by the growing global demand.

He pointed that in the past decade FCC contribution to propylene production has increased by 40%. During the same time, TechnipFMC’s high propylene FCC licenses have increased from 5 to 55%, evincing the industry interest in upgrading refineries to take advantage of the propylene demand uptrend.

He said that while lower gasoline demand is driving refiners to operate at reduced throughputs, FCC revamps prove to be the effective tool to maximize assets and utilize them to profitably produce petrochemicals. The approach to high propylene yield includes using highly selective catalyst, operating at high severity, and retrofitting FCC to state-of-art new technologies. He also discussed the role of operating parameters in shifting FCC functionality from gasoline specific to propylene specific depending on severity.

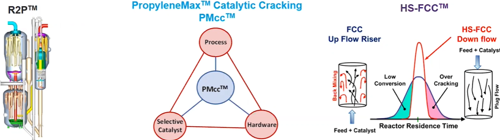

Mr. Singh showcased TechnipFMC’s 3 distinctive high propylene FCCU technologies –

- R2P (Riser to Propylene) – featuring a separate riser, two stage regeneration, and a highly selective catalyst and 10-14% propylene yield

- PMcc (PropyleneMax Catalytic Cracking)– featuring an advanced synergistic integration between, process, catalyst and hardware, and a proprietary catalyst system with 15-21 % propylene yield

- HS-FCC (High Severity FCC) – featuring a unique downflow reaction system which maximizes gas-solid contact at short contact times to achieve highly selective yields of 15-20%

While detailing the process of FCC revamps he emphasized the importance of technology selection based on refiners need, flexibility of operation, and integration with other refinery units.

Mr. Singh outlined the key parameters for higher propylene yield as low hydrocarbon partial pressure, use of selective catalyst, and high severity. He discussed supportive processes like Omega, FlexEne, and Metathesis, that are used in conjunction with optimal FCC to further augment propylene yields.

Mr. Singh shared examples of FCC revamp studies starting with the planning phase and following with the design and subsequent modifications phase for maximum asset utilization. TechnipFMC conducted a breakpoint analysis to determine the configuration providing maximum margin for the revamp within the multiple constraints applicable for the system; before proceeding from the planning to the design and engineering phase. They modified the reactor design and some of the operating parameters such as ROT, catalyst/oil (C/O) ratio, ZSM-5, to achieve a 175% increase in propylene yield.

He discussed FCC revamp options for retrofitting existing FCCUs and potential propylene boost attainable with each option. He further discussed phase wise process of refinery expansion and integration of the crude to chemicals route. He pointed that the route to maximum petrochemical integration is based on three significant configurations:

- High olefin FCC

- Steam cracker Unit and

- Aromatics complex

He closed the presentation by sharing TechnipFMC’s futuristic vision for advanced refinery-PetChem integration which can enhance crude to chemical conversion to >50% as compared to <10% in conventional refining. He also mentioned that attendees can access details to the PMcc technology via an article in the current (September, 2020) issue of Hydrocarbon Processing.

IRPC Americas ONLINE continues through Wednesday, September 23. Visit www.irpc-americas.com for more information.

Comments