Digital Feature: Enhancing ethylene cracker radiant tube integrity through innovative robotic inspection

The ethylene cracker plays a crucial role in the petrochemical industry, producing over 200 MMtpy of ethylene, which is the major building block for plastics, synthetic rubber, lubricants and various chemicals. The radiant tubes within the ethylene cracker function as high-temperature reaction vessels and endure harsh conditions, including high temperatures and corrosion. Their stability significantly impacts the safety and economic efficiency of the entire ethylene cracking unit.

According to statistics from the AIChE’s Ethylene Producers' Committee and data from Sinopec, radiant tube failure ranks as a primary cause of unplanned shutdowns in ethylene cracking furnaces.1 In recent years, with the continuous improvement of radiant tube material property and the optimization of ethylene production process parameters, the overall service life of these radiant tubes has increased. However, due to extreme operating conditions, tube failures still occasionally lead to unplanned cracker shutdowns.

Tube failure mechanism. The causes of tube failures have been extensively studied,2,3,4,5,6,7 revealing the complexity of furnace tube failure. These factors include carburization, creep, aging and the operational history of the process, among others. Carburization of the furnace tubes is considered a primary contributor to material failure. Carburization is characterized by carbon enrichment in the inner wall and extra carbide formation from the inner to the outer wall. Consequently, material strength and ductility decrease significantly, resulting in very low mechanical resilience when the tube is exposed to thermal stress. In cases of severe carburization, the tube becomes susceptible to through-wall crack propagation, leading to tube leakage and emergency shutdowns of the cracker unit.

The principle of carburization detection. Carburization measurement is crucial for ensuring the stable operation of ethylene crackers. Various standards and methods—such as NACE TM0498 and Chinese NB/T 10618-2021—provide clear guidance for monitoring carburization in furnace tubes. However, these etching measurement methods are destructive and, as a result, cannot offer real-time analysis and assessment during cracker maintenance. To overcome this limitation, portable carburization detection devices have been developed.

Initially developed by tube manufacturing companies, these devices have undergone continuous improvements by universities and independent institutes.8,9,10,11,12 They operate on the principle of magnetic testing. When carburization occurs in heat-resistant alloys [e.g., HP and 35Cr-45Ni (35 chromium-45 nickel) microalloy], the magnetic properties of the material matrix shift from non-magnetic to ferromagnetic. The degree of carburization can be determined based on the magnitude of the detected magnetic response. More precisely, both eddy current coils and Hall-effect sensors have been employed to detect the magnetic response. Due to their rapid and non-destructive nature, portable carburization detectors have found application in petrochemical companies.

Portable carburization detectors have certain limitations. They necessitate the use of scaffolding and often offer measurements at specific heights of the furnace tubes, which cannot encompass the entire length of the tubes. Carburization is a thermodynamic process influenced by various factors, including not only the temperature field generated by burners but also the feedstock reaction process, flow turbulence within the tube, coking and decoking processes, and the corrosion resistance of the tube material. Consequently, the distribution of carburization can be intricate, and taking measurements at specific heights may not provide a comprehensive understanding of the situation.

To tackle this challenge, crawling robots have been developed and equipped with carburization detectors.13,14 These robots have the potential to offer comprehensive carburization detection within furnace tubes as they can traverse the entire length of the tube, providing more thorough data. However, at the time of this publication, there are limited industrial application reports regarding the implementation of crawling robots for carburization detection. This suggests that this field is still in the research and development phase. Nevertheless, the potential and prospects for this technology are promising, and it is anticipated to bring substantial improvements to the maintenance and performance enhancement of ethylene cracking furnaces.

A proprietary inspection systema, developed by the author’s company, is an advanced intelligent crawling inspection system that covers the entire length of the tubes (FIG. 1). It integrates machine vision, artificial intelligence (AI) analysis, carburization and crack detection technologies, providing comprehensive multi-aspect inspection data.

FIG. 1. A view of the proprietary inspection systema in operation at an ethane cracker.

Technical characteristics of the proprietary inspection systema are detailed in TABLE 1.

|

Defects |

Carburization, crack, bulging, outer surface |

|

Inspection area |

Entire length, full circle |

|

Tube’s outer diameter, mm |

50–250 |

|

Number of probes |

2–32 |

|

Space between tubes |

|

|

2 probes, mm |

15 |

|

4–32 probes, mm |

30 |

|

Inspection time |

Tube: 1 min, cracker unit: 1 d |

|

Crawling |

Electric motor |

|

Communication |

Wifi |

|

Tube protection |

Self weight < 3 kg, rubber protection |

TABLE 1. Technical characteristics of the proprietary inspection systema

In terms of carburization detection, this system was developed based on the eddy-current coils method and offers impressive data in a novel way. It achieves detection accuracy of < 1 mm in the height direction. In the circumferential direction, it can divide the radiant tube into 2, 4, 8, 16 or 32 segments—based on the tube's outer diameter—and perform carburization detection in each segment. This means that on a single long radiant tube, the system takes approximately 1 min for detection, generating nearly 100,000 data points, covering every corner of the tube to ensure nothing is missed. The data is presented intuitively through map views, providing a clear visualization of the carburization status.

Inspection results. An inspection was conducted at an ethane cracker with a nameplate capacity of 1.25 MMtpy. Before the inspection, information such as tube dimensions, tube grades and the gap distance between tubes was provided by the end user. During the inspection, crawling robots initiated the inspection from the ground floor and progressed upward, performing a minimum of two crawls for each tube. Simultaneously, the proprietary inspection systema conducted tasks, including an AI-based visual inspection of the tube's outer surface, carburization measurement and crack detection. It identified defects within the tubes from various aspects and evaluated the remaining life of each tube. If any suspicious defects were identified, the system rechecks the defect location repeatedly until the presence of the defect is confirmed or ruled out.

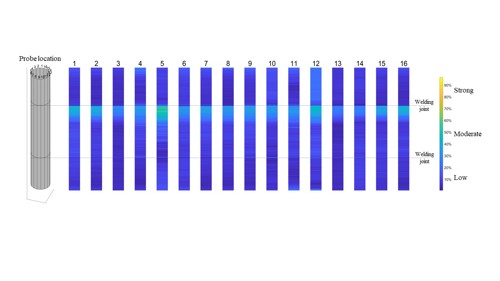

The inspection results for a 1-yr serviced tube are presented in FIG. 2.

FIG. 2. Carburization map of a 1-yr serviced tube made from 35Cr-45Ni microalloy.

This tube has an outer diameter of 174 mm, a wall thickness of 8 mm and stands at a height of approximately 13 m. It is made of 35Cr-45Ni microalloy and is composed of three tube sections and two welding joints, with the feedstock flowing downward within the tube. During the inspection, 16 carburization probes were used in the circumferential direction, and each column chart in FIG. 2 corresponds to the inspection results of each probe. The color gradient change differentiates the degree of carburization, with blue indicating low carburization and yellow indicating high carburization. It was observed that the areas with medium carburization were mainly concentrated in the middle tube section, which aligns with the higher temperature field generated by the burners. Furthermore, the medium carburization area was primarily located below the upper welding joint. A hypothesis suggested that this concentration was due to the turbulence effect of the feedstock caused by the imperfect smoothness of the weld joint root, creating a high-temperature zone in that area, which, in turn, accelerated the carburization process. A more accurate analysis would require further confirmation through computational fluid dynamics simulations and materials metallurgical analysis.

Benefits. Due to confidentiality reasons, other inspection results cannot be divulged in this article. Nevertheless, this inspection systema has provided evidence that carburization in the furnace tubes was influenced by various factors, such as the temperature field, feedstock flow turbulence, feedstock reaction extent and the corrosion resistance of the tube material, among others. These findings underscored the complexity of the carburization process and its unpredictable distribution within tubes. Based on such carburization inspection data, customers can gain multiple benefits and applications, including but not limited to:

- Reduced operational risk: Early identification of heavily carburized tube areas during maintenance enables timely and precise replacement if field conditions allow. Otherwise, enhanced daily surveillance of critical areas should be maintained during operation. This mitigation strategy reduces the risk of unplanned shutdowns and prevents significant economic losses.

- Optimized process performance: Insights into process performance, such as whether the process temperature is too high, leading to faster-than-expected carburization in the entire unit, or if the abnormal performance of a burner causes localized overheating. End users can use this data to adjust and optimize process parameters, improving the overall performance and lifespan of the unit. What is even more significant is that data-driven decision-making is made possible, allowing an increase in ethylene cracker production rates within safe limits, resulting in substantial economic benefits, especially when the ethylene market price is favorable.

- Intelligent maintenance: End users can achieve more precise tube replacements based on inspection results, avoiding over-replacement and reducing maintenance costs. During the tube replacement process, heavily carburized materials can increase the crack susceptibility in welding joints, affecting the maintenance progress and delaying the unit's restart. Carburization inspection data enables customers to develop more accurate replacement plans, ensuring efficient and timely replacement work.

It is worth mentioning that the failure mechanisms in radiant tubes involve not only carburization but also other aspects, including creep bulging and brittle cracking. This is why the proprietary inspection systema not only conducts carburization detection but also simultaneously checks for issues such as bulging and cracks. The author believes that to comprehensively assess furnace integrity, a multi-aspect analysis must be conducted.

ACKNOWLEDGEMENT

The author would like to acknowledge Yantai Manoir Heat Resistant Alloy Co. Ltd for providing carburized samples for carburization measurement calibration.

NOTE

a CastNewX Technology’s TubeDoctor™

REFERENCES

2 Jakobi, D. and R. Gommans, “Typical failures in pyrolysis coils for ethylene cracking,” Metal Dusting, Carburisation and Nitridation, EFC series, 2007.

3 Kus, S., et al., “Failures of high-temperature alloys in ethylene furnaces,” NACE Corrosion, San Antonio, Texas, 2014.

4 Al Shawaf, A. H. and M. K. Maity, “High-temperature alloys failures in petrochemical furnaces,” NACE Corrosion, April 2018.

5 Han, Z., X. Guoshan, L. Cao, L. Wang and G. Sun, “Material degradation and embrittlement evaluation of ethylene cracking furnace tubes after long-term service,” Engineering Failure Analysis, March 2019.

6 Guan, K., H. Xu and Z. Wang, “Analysis of failed ethylene cracking tubes,” Engineering Failure Analysis, June 2005.

7 Lian, X. M., X. D. Chen, T. Chen, J. Ye and J. F. Sun, “Carburization analysis of ethylene pyrolysis furnace tubes after service,” Procedia Engineering, 2015.

8 Silva, I.C., et al., “Structural and magnetic characterization of a carburized cast austenitic steel,” Scripta Materialia, November 2008.

9 Stevens, K. J., A. J. Tack, C. W. Thomas and D. Stewart, “Through-wall carburization detection in ethylene pyrolysis tubes,” Journal of Physics D: Applied Physics, 2001.

10 Hasegawa, K., T. Oikawa and N. Kasai, “Development of an eddy current inspection technique with surface magnetization to evaluate the carburization thickness of ethylene pyrolysis furnace tubes,” Journal of Nondestructive Evaluation, July 2012.

11 Arenas, M. P., et al., “Magnetic evaluation of the external surface in cast heat-resistant steel tubes with different aging states,” Journal of Magnetism and Magnetic Materials, June 2018.

12 Chen, T., X. Chen, J. Chen, J. Zhang and C. Liu, “Magnetic method for rapid detection of carburization degree of Fe-Cr-Ni series high-temperature heat-resistant alloy,” J. Pressure Vessel Technology, October 2022.

13 Tiyawongsakul, T., “Carburization inspection robots for radiant tubes inside ethylene cracking furnaces,” Hydrocarbon Processing, August 2017.

14 Khodamorad, S. H. and D. F. Haghshenas, “Inspection of carburization and ovalness in ethylene cracking tubes by using a semi-robot,” Engineering Failure Analysis, October 2012.

About the author

Minghao Zhang is the founder of CastNewX Technology Co., Ltd. He has more than 10 yr of experience in heat-resistant alloy research and development and expertise in pyrolysis furnaces in the petrochemical industry. He specializes in developing innovative solutions for pyrolysis furnace services. Dr. Zhang earned a PhD in metallurgy and material science from MINES ParisTech in France.

Comments