Sponsored Content: Fluidized bed Methanol to Gasoline (MTG)

ExxonMobil’s methanol to gasoline (MTG) process selectively converts methanol to a single fungible liquid fuel and a small LPG stream. The liquid product is conventional gasoline with very low sulfur and low benzene, which can be sold as-is or blended with ethanol, methanol or with petroleum refinery stocks. This minimizes offsite and logistic complexity and investment for synthetic fuel distribution.

Proven process

Methanol-to-gasoline chemistry was discovered by ExxonMobil scientists in the 1970s. Over years of extensive studies and pilot plant operations, ExxonMobil developed the fixed bed MTG process, and subsequently developed the fluid bed version of MTG in part through collaboration with others in the industry.

Fluid bed MTG process overview

Compared to fixed bed MTG, fluid bed MTG demonstrates overall advantages in CAPEX, OPEX, operation reliability, steady product quality, carbon intensity, and more. Today, ExxonMobil is focusing on actively licensing fluid bed MTG over fixed bed MTG. The unique MTG catalyst is the science that limits the synthesis reactions to ~11 carbons, which is exactly the gasoline range.

In the fluid bed MTG design, raw methanol feedstock, including typical 4wt% water and 96wt% methanol, is vaporized and superheated through a series of heat exchangers, then fed into the fluid bed reactor for conversion into hydrocarbons and water.

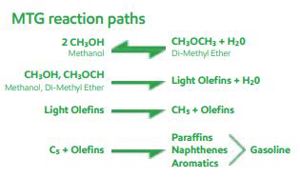

At the MTG reactor conditions, light olefins oligomerize into higher olefins, which combine through various reaction paths into paraffins, naphthenes, and methylated aromatics.

In the 1970’s, ExxonMobil studied the fluid bed MTG process in 4BPD of MeOH pilot plant with very successful results. In the 1980’s, ExxonMobil took an extra step to conduct a 100 BPD of MeOH demonstration plant testing, also with very successful results. In March 2015, ExxonMobil and Sinopec Engineering Group (SEG) announced a joint technology development agreement for advancement of a fluidized-bed MTG technology. Today, we are working with our licensees on constructing a full pilot plant for fluid bed MTG in South America.

Proven performance

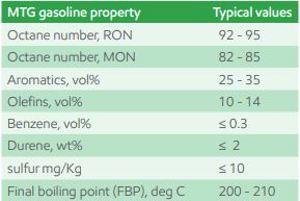

The conversion of methanol to hydrocarbons and water is virtually complete with the product being a mixture of synthesis hydrocarbons and water with a limited amount of C₂- gases. Production yields, product qualities, and catalyst performance are stable during operation. The liquid product is conventional gasoline with virtually no sulfur and low benzene, which can be sold as-is or blended with ethanol or methanol or with petroleum refinery feedstocks.

Technology readiness

Well-proven process and catalyst, rich ongoing pilot plant experience and high interest from customers have paved the foundation for the prospect of commercial scale units.

Why ExxonMobil Catalyst and Licensing?

Advance your refining, gas, and petrochemical business by improving operations, increasing capacity, lowering costs, improving margins, and reducing emissions using our differentiated high performance specialty catalysts, advantaged processing technologies, and worldwide operational expertise. With a proven commitment to helping customers implement best practices for the operation of safe, reliable, and efficient facilities that have delivered better results for 60 years, choose ExxonMobil’s Catalyst and Licensing Business.

Collaborate with us today.

Comments