2021 AFPM Annual Meeting Virtual Edition: Suppressing unappealing steam plumes from wet gas scrubbers

YVES HERSSENS, Business Development Leader, DuPont Clean Technologies

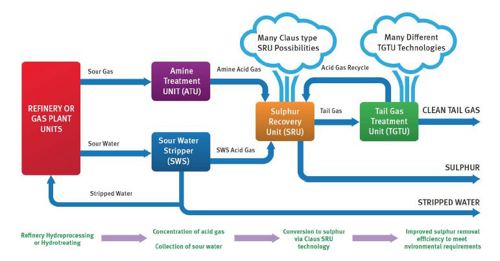

Increasingly stringent air quality standards have pushed the refining industry to steadily reduce sulfur dioxide (SO2) emissions from sulfur recovery units (SRUs) and/or their tail gas treatment systems. However, the wet scrubbers generally used to clean flue gases add water vapor, which condenses on exiting the stack and leads to a visible steam plume (FIG. 1). The general public can mistake this harmless plume for a sign of pollution when, in fact, the refinery has worked hard to improve air quality. For many years, refiners did little to eliminate water vapor plumes as installation and operating costs for suppression technology were high. Designed to work with the DynaWave® reverse jet scrubbers in SRU applications, the Sennuba™ process, licensed by DuPont Clean Technologies (DuPont), prevents the formation of an unappealing visible steam plume when clean combustion gases are emitted to air.

FIG. 1. A visible plume from a DynaWave® scrubber operating without Sennuba™ process.

To date, three main options have prevented steam plume formation after a wet scrubber: sub-cooling the gas within the scrubber, diluting the clean gas after the scrubber, or reheating the clean gas after the scrubber. All have presented a number of issues.

To sub-cool the gas within the scrubber, cooling water is needed to lower the temperature of the scrubber circulation loop and reduce the gas temperature from more than 140°F to ≤ 86°F. This has the drawback of not only leading to increased water consumption, but also requires a redesign of the scrubbing system.

To dilute the gas after the scrubber, hot air or clean combustion gas sources can be mixed with the flue gas. This process de-saturates the gas and lowers the dew point, but it generally requires the installation of a burner at the bottom of the stack to dilute and heat the gas, pushing up energy use. In certain areas, this option is unavailable due to local regulations.

If a visible steam plume is suppressed by reheating the gas after the scrubber, this is often done with an external energy source, which translates into high operating costs. Another option is to employ a gas-to-gas heat (GGH) exchanger that uses the heat of the hot dirty gas upstream of the scrubber to raise the temperature of the exit gas. A heat exchanger, however, comes at a cost and is also liable to plugging in this application, as shown in FIG. 2. GGH exchangers further increase the risk of SO2 leaking from the hot dirty side to the clean gas side after the scrubber.

FIG. 2. Plate-type heat exchanger, which is liable to plugging in this application.

The Sennuba process takes a similar approach with a key difference: it works in conjunction with the DynaWave reverse jet scrubbing system that is extensively used for SRU tail gas treatment to guarantee low air emissions at any given time. This wet scrubbing solution combines multiple functions in one single vessel, and has proven that it can handle high turndown ratios, variations in incoming acids, and inlet temperatures of up to 2,200°F in SRU offgases.

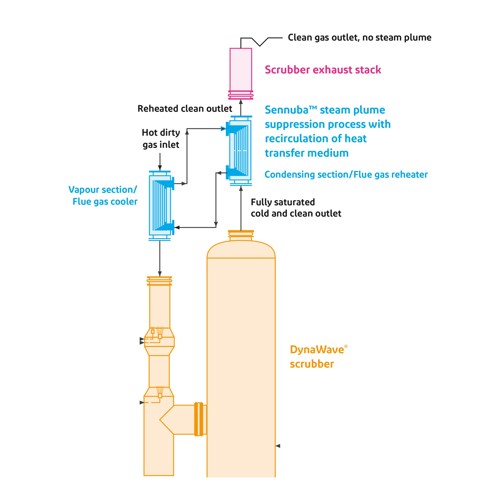

The Sennuba design. Rather than relying on an external energy source, the Sennuba process (FIG. 3) uses the energy of the hot dirty gas upstream of the scrubber to heat the cool clean saturated gas leaving the scrubber. The process also prevents dirty gas from leaking to the clean side.

FIG. 3. DynaWave® scrubber with Sennuba™ steam plume suppression process.

The technology employs two specialized thermosyphon heat exchangers and a heat transfer medium to heat the cool gas with energy transferred from the hot gas. By recovering energy in this process and using it to heat the exit gas of the DynaWave scrubber, the Sennuba process eliminates the high operating costs associated with traditional steam plume suppression methods.

In addition, the use of a heat transfer medium with two separate heat exchangers prevents SO2-containing process gas from leaking directly to the clean outlet of the scrubber and, thus, to the atmosphere.

The thermosyphon ensures there is no forced circulation of the heat transfer medium, while customized heat exchanger technology avoids the plugging and corrosion issues to which traditional plate type heat exchangers are commonly prone.

The Sennuba steam plume suppression process was developed specifically to enable oil refiners to combine a cost-effective tail gas treatment unit (TGTU) technology of their choice with the low-emissions guarantees of the DynaWave technology (FIG. 4) without generating a visible steam plume, which can be perceived as unappealing to the refinery’s surrounding communities. This offers refineries greater dependability, a smaller overall footprint, simpler operation, reduced maintenance and significantly lower capital investments in their effort to meet regulatory SO2 emissions limits from Claus plants without interruption during maintenance or malfunction of any upstream main TGTU.

FIG. 4. The DynaWave® scrubber cuts any remaining SO2 emissions, regardless of the efficiency of the SRU and TGTU selected.

By adding the integrated Sennuba plume suppression technology to its DynaWave scrubbing system, DuPont has expanded its dedicated refinery scrubbing and air pollution control solutions, enabling the refining industry to meet clean air targets while reducing public concern about visible, invisible and/or perceived pollution, including steam plumes.

Takeaway. Visible steam plumes are harmless but unsightly and cause for potential alarm to local communities. Refineries that want to prevent the formation of visible steam plumes after investing in pollution control technology to improve air quality have a range of options, which has now been expanded with the Sennuba technology. Designed specifically to treat visible plumes from DynaWave wet scrubbers in SRU applications, it offers lower capital and operating costs, minimal risk of plugging and improved corrosion control.

About the author:

YVES HERSSENS is the Business Development Leader for DuPont Clean Technologies. After working with ExxonMobil in the Netherlands and in Belgium, he joined MECS (wholly owned subsidiary of DuPont) in 2005. Over the years, he has held various positions spanning multiple domains, from finance and accounting to sales and marketing, global technology licensing and leadership. Herssens now focusses on the further development of the scrubbing business on non-sulfuric acid applications in Europe, Africa, the Middle East, India and CIS subregions, including aftermarket support to existing DynaWave® and Belco® customers. He holds an MS degree in business engineering and international management from the University of Antwerp.

Comments