2020 AFPM Summit: Early planning of reactor unloading gives safety, cost, time benefits

Early planning of reactor unloading gives safety, cost, time benefits

ADRIENNE BLUME, Executive Editor, Hydrocarbon Processing

At AFPM's virtual Summit on Wednesday, an excellent afternoon session on catalyst unloading included Alfredo Romero, Field Services Manager for Eurecat U.S. Inc.; Danny Kurtz, Consultant/Sales for Cat-Spec Ltd.; and David Wilkins, Consultant for Petroval. The speakers shared planning implications and technology options for unloading catalyst from a reactor.

Planning a reactor unloading. The first questions to be asked when planning reactor unloading, Romero noted, include: How much money can be saved by planning ahead of time for reactor unloading? Who will make the decision about the spent catalyst—maintenance, operations, health and safety, etc.? What can be anticipated about the unloading—what is the history of the unit? Does it have a history of plugging or free-flowing during previous turnarounds?

A review of maintenance logs is essential for understanding how a specific reactor may behave during loading and unloading. "This is very important for young engineers who are heading into their first turnaround," Romero said. "You have to do a lot of homework ahead of time so that you can understand what's going to happen."

Wilkins noted that early tracking and managing catalyst drums, bins, bags, etc. is essential for proper catalyst management onsite and during ship-out. It also helps maximize recovery or reuse of the catalyst and saves cost.

Kurtz agreed that all tracking and decisions should be done a year in advance to avoid paying demurrage fees on catalyst bins. Romero explained that it is necessary to consider spent catalyst length for regeneration. This will also determine the unloading technique used. A certain particle length (around 2.5 mm for solid catalyst) must be achieved to avoid problems.

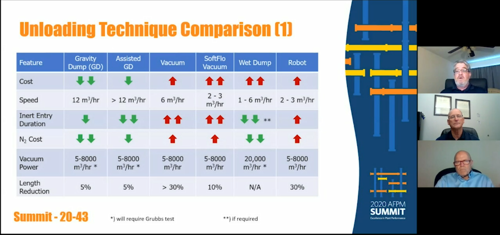

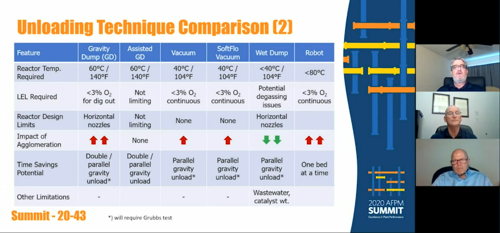

Comparison of unloading methods. The speakers offered a comparison of various unloading techniques (FIG. 1 and FIG. 2) with regard to critical features including total cost, speed, inert entry duration, nitrogen cost, vacuum power, length reduction, required reactor temperature, lower explosive limit (LEL) requirement, reactor design limits, impact of agglomeration and potential time savings.

FIG. 1. A comparison of various unloading techniques.

FIG. 2. A comparison of various unloading techniques.

Kurtz noted that the vacuum dump method is often chosen if the reactor is showing channeling or maldistribution and if the catalyst will not be reused. Meanwhile, the soft-flow vacuum method cuts down attrition by 50%, although it requires double the square footage for equipment.

The wet dump method is chosen when catalyst will not be reused. It cuts nitrogen cost to cleanup nitrogen only, and it achieves the best passivation on the vessel; however, it requires more cleanup time and wastewater disposal. A key question to ask for wet dumps is whether the reactor and the footing will hold the weight of the water.

Finally, remote (robotic) removal technology is a new process that increases safety by not requiring personnel entry to the reactor. Robotic methods will continue to be improved, making remote removal the way of the future.

Kurtz noted that safety issues around the temperature of the vessel are paramount. "Every turnaround, I get asked the same question. Management always seems to want to dump reactors in the 120°F–140°F range—but remember that your catalyst is actually the heat sink, pulling heat from the walls and out. You can free-dump catalyst at 140°F, but you still have to get inside the hole, and the temperature must be 100°F or less to get an individual inside the hole."

Failing to pull heat out of the walls prior to personnel entry can add days of reactor cooling time onto the catalyst unloading process. In this sense, a wet dump is beneficial because chilled water can help cool the vessel at a faster rate, Kurtz said.

Technologies for assisted gravity unloading. For the gravity dump method of catalyst unloading, either external or internal assistance is needed to work around the angle of repose. A number of technologies are available for this purpose.

Carbodump introduces liquid CO2 in a cartridge into the catalyst bed. The CO2 is heated and creates expansion to agglomerate the catalyst. Carbodump helps shake up the bed and break up the catalyst to get it flowing again.

Catflow technology can work independently of or in conjunction with the Carbodump process. Catflow is a nitrogen-injection system for horizontal dump nozzles that works well on a free-flowing catalyst bed. "This is a much safer way to work horizontal dump nozzles than using old-style augers inside of the reactors," Wilkins commented. Catflow reduces the amount of time personnel are inside the reactor and enables a soft flow of catalyst that increases catalyst yield for recovery or reuse.

ULTICAT is a remotely actuated vacuum system. The vacuum hose is inserted through the dump nozzle to remove the remainder of the catalyst after gravity unloading. It eliminates reactor entry and uses a soft vacuum that will not harm the catalyst. The time required is equivalent to manual sweeping or vacuuming, and it gives improved yield of catalyst for reuse.

A soft-flow vacuum cuts the rate of attrition in half but doubles the required footprint. If the square footage is available and the catalyst needs to be optimized for reuse, then the soft-flow vacuum method is a viable choice. The process must be planned out ahead of time to ensure that the required space is available.

Remote (robotic) catalyst unloading is highly beneficial to personnel safety. If a top distributor tray is present, then the tray must be removed for manual lowering of the robot; however, entry time is reduced if the material is not too agglomerated. Remote unloading requires the same amount of nitrogen as any other vacuum method.

Finally, the speakers shared examples of conventional unloading methods including jackhammering, hydroblasting and controlled explosion. These options are generally time consuming, come with increased risk and extend the inert entry time.

In conclusion, Kurtz emphasized the idea of pre-planning a reactor unloading well ahead of time. "By planning a year out, always set yourself up for success by involving everyone in environmental safety so that when you start the job, you've already knocked out up to 90% of the hurdles. This makes the turnaround much more fluid and achievable."

Comments