Digital Feature: Reducing the carbon impact of oil and gas projects toward net-zero with operations science

J. Choo, Strategic Project Solutions, San Francisco, California

To support the Paris Agreement, many oil and gas owner-operators have instituted carbon pricing, are working diligently on reducing methane emissions, incorporating carbon capture and storage solutions, and developing renewable energy sources. Other industries (e.g., data center owner-operators) have similar challenges related to decarbonizing energy consumption to not only achieve net-zero but also aiming to become carbon-free.1 The success of these initiatives focuses on reducing greenhouse gas (GHG) during operations, which is critical to achieving the targets set by the Paris Agreement.

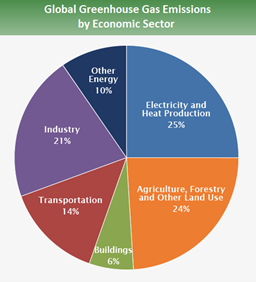

The Paris Agreement, adopted at the UN Climate Change Conference (COP 21) in Paris on December 12, 2015, and entered into force on November 4, 2016, is a legally binding international treaty that attempts to hold the increase in the global average temperature to 1.5°C above pre-industrial levels. To achieve this target, GHG emissions must decline by 43% by 2030, with its peak being before 2025.2 Among the GHGs, data from 2010 shows carbon dioxide (CO2) representing 76% of the GHG, methane (CH4) 16%, nitrous oxide (N2O) 6% and fluorinated gases 2%, which are generated from various economic sectors.3

Oil and gas companies have been tasked with playing a key role. It is worthwhile noting that the sectors directly involved in the delivery of capital projects, namely, electricity and heat production, transportation and industry, account for 60% of GHG emissions (FIG. 1). If we look at the general building industry as an example, buildings account for 40% of annual global CO2 emissions, with concrete, steel and aluminum accounting for 23%.4 For buildings, it is estimated that roughly 50% of the carbon emissions over the next three decades will come from carbon emitted from manufacturing, transportation and installation of building materials—i.e., embodied carbon. The Leadership in Energy and Environmental Design (LEED) rating system, which has been in development for nearly 30 yrs and is widely accepted and recognized in the building sectors, has recognized the importance of minimizing embodied carbon by focusing on what products are being permanently installed within buildings.5

However, none of these initiatives or approaches actively minimize the GHGs that are emitted throughout the delivery of capital projects and their supply network. This is a significant opportunity that can be capitalized to further reduce not only emissions but also the cost and duration of project delivery.

FIG. 1. U.S. CO2 emissions by source, 2020. Source: U.S. EPA.

Why the current approach to project delivery is insufficient to address carbon reduction needs. The predominant approach for the delivery of capital projects centers around maximizing productivity and predictability.6 These two factors directly correlate to the development of modern project management thinking and have had a significant influence on how projects are delivered today and form the basis of current trends in thinking about how to improve performance.

The Era of Productivity (Era 1) has seeded the thinking that maximizing productivity (measured as output per person-hour) in every phase and operation will be key in minimizing costs and duration. The Era of Predictability (Era 2) spawned the idea that through proper project administration—such as integration, scope, time, cost, quality, human resource, communications, risk, procurement and stakeholder management7—will result in predictable project outcomes.

Although there are exceptions, most owner-operators and engineering, procurement, construction, and construction management companies (EPC/EPCMs) typically subscribe to Era 2, and those that are involved in direct-hire work (e.g., engineering, fabrication, logistics and installation) mainly subscribe to Era 1 thinking. This combination creates a very risky situation for all those involved due to the means used to achieve their individual objectives, namely productivity and predictability.

In Era 1 thinking, idle labor or equipment is a major faux pas that is to be avoided as much as possible. The way most organizations prevent idle labor and equipment is by ensuring that there are always “things waiting to be worked on,” whether it be information for design and engineering or materials for fabrication, delivery and installation, so that as much of “things being worked on” can be executed. Since there is variability and uncertainty in every facet of project delivery, having an abundant number of things “waiting to be worked on” is seen as positive and obviously better than not having them. This approach aligns well with Era 2 thinking since this is seen as an effective means to achieve predictability, as well. However, if there is a perceived schedule risk, time contingencies are added to ensure that the material and equipment (permanent and temporary) have arrived, and certain activities are completed sufficiently ahead of when the output is needed. In most projects, this results in a massive amount of inventory—things waiting to be worked on and things being worked on—resulting in additional handling and holding, as well as more cash than necessary being tied up. More importantly, managing additional inventory creates additional GHG emissions, but there is no way to visualize, measure or optimize inventory within Era 1 or Era 2 thinking. Therefore, a new framework is required to optimize project delivery with concurrent emphasis on emissions, cost, schedule and cash flow.

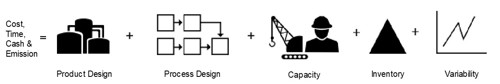

Fulfilling the obligations of decarbonization while increasing profitability. Trying to optimize project delivery for all the previously stated factors is impossible without science to describe the levels that affect these factors and the relationship between these levers. The Era of Profitability (Era 3) is fundamentally different from Era 1 and 2 in that Era 3 views projects as production systems that can be optimized using project production management and its underlying science, operation science. Project production management views cost, time, cash flow and emissions as a function of product design (what is being made), process design (how the design, engineering, fabrication, delivery, installation, testing and commissioning is performed), capacity (labor, equipment and space to do the work), inventory (things waiting to be worked on and things being worked on) and variability (variability in batch sizes, durations and capacity, among others)(FIG. 2). The optimal tradeoff between capacity, inventory and variability can be determined by utilizing operations science.

FIG. 2. The five levers of project production management

Although a full explanation of operations science is not the intent of this article, one of the key ideas to note is that the reduction of variability creates an opportunity to reduce capacity and inventory simultaneously, unlike traditional Era 1 and Era 2 thinking, where one must increase for the other one to decrease. By systematically reducing variability throughout project delivery and its supply network and optimizing capacity and inventory tradeoffs, cost, schedule, tied-up cash and emissions can be reduced.

For example, in a recent oil and gas field development project, the author’s company played a crucial role in enabling a 146% increase in net present value, a 20% reduction in cost and 27% less cash required. Since reducing cost and cycle time simultaneously requires doing more with less, the amount of carbon emissions associated with a reduction in labor, equipment and space is substantial.

Leadership in carbon reduction needs solutions that address the gap in current project delivery. While many organizations involved in the delivery of oil and gas projects are actively pursuing ways to reduce emissions during facility operations, there remains a substantial opportunity to reduce emissions throughout project delivery, including its supply network.

However, the predominant approach to project delivery based on Era 1 and Era 2 thinking is resulting in undesirable project results, not only in terms of schedule, cost and cash flow, but also in emissions. For more than 20 yrs, many organizations and projects in the oil and gas industry have implemented and benefited from the project production management approach with an emphasis on schedule, cost (monetary) and cash flow. By extending traditional costs to account for emissions costs, project production management and operations science provide an effective way to achieve desired project outcomes, while reducing carbon impact and meeting owner and investor goals.

LITERATURE CITED

1 Google, “Carbon commitments: Building a carbon-free future for all,” online: https://sustainability.google/commitments/carbon/#

2 UN, “The Paris Agreement,” online: https://unfccc.int/process-and-meetings/the-paris-agreement

3 U.S. Environmental Production Agency (EPA), “Global Greenhouse Gas Emissions Data,” online: https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data

4 Architecture 2030, “Why the built environment?” online: https://architecture2030.org/why-the-building-sector/

5 U.S. Green Building Council, LEED Reference Guide for Building Design and Construction, November 2013 (updated August 2020).

6 Zabelle, T. R., R. J. Arbulu and H. J. J. Choo, “Conceptual frameworks underpinning project delivery and implications for optimizing project outcomes,” December 2016.

7 Project Management Institute, A Guide to the Project Management Body of Knowledge (PMBOK Guide), 2021.

Comments