Dow to build world-scale ethylene plant by 2017 at Freeport complex

(Thursday afternoon update adds details and photos throughout.)

By Ben DuBose

Online Editor

HOUSTON -- Dow Chemical said Thursday that it will build a world-scale ethylene plant at its chemical hub in Freeport, Texas, as part of a plan to further connect US operations with cost-advantaged feedstocks available from increasing US shale gas supplies.

Ethylene production is projected to start up in 2017, the company said, noting that feedstock supply arrangements are in the works.

Ethylene production is projected to start up in 2017, the company said, noting that feedstock supply arrangements are in the works.

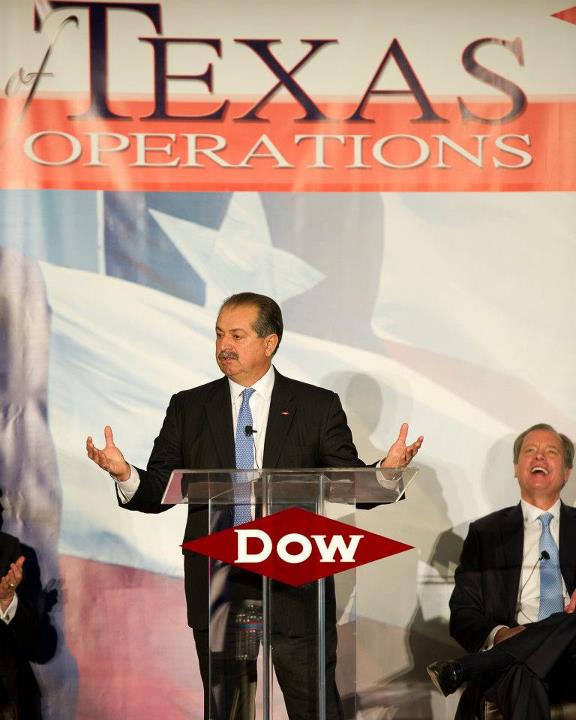

“For the first time in over a decade, US natural gas prices are affordable and relatively stable, attracting new industry investments and growth and putting us on the threshold of an American manufacturing resurgence,” said Andrew N. Liveris, Dow CEO.

The new cracker in Freeport, located about 45 miles southeast of Houston on the Gulf of Mexico coast, will have a capacity of 1.5 million tpy and be able to use both ethane and propane as feedstock.

"Dow’s announcement is further evidence that the chemistry industry is a growth engine helping to revitalize America’s manufacturing sector,” said Cal Dooley, CEO of the American Chemistry Council (ACC) trade group.

“Thanks to abundant, affordable natural gas, the nation’s chemical companies have entered an era of renewed global competitiveness which can help generate new domestic investment, jobs and manufacturing exports," Dooley continued.

"It’s great news for the many industries that rely on chemistry and plastics, including auto manufacturing, construction, agriculture, health care, and technology.”

Construction details

The new ethylene facility at Dow Texas Operations will employ up to 2,000 workers at its construction peak, the company said.

Over the next five to seven years, Dow estimates that the project, together with all other planned projects in its US investment plan, will employ up to 4,800 workers during peak construction and support over 35,000 jobs in the broader US economy. The primary competition to host the Dow cracker came from Louisiana, according to Texas Governor Rick Perry, who spoke at a Thursday ceremony in Freeport.

The primary competition to host the Dow cracker came from Louisiana, according to Texas Governor Rick Perry, who spoke at a Thursday ceremony in Freeport.

"Louisiana is always going to be a competitor when it comes to the petrochemical industry," said Perry, who added that the project would cost $1.7 billion.

For selecting Texas as the site, Dow will receive $1 million through the Texas Enterprise Fund, he said.

"This is the type of environment that [companies] want to be associated with," said Perry. "This is where they want to do business."

Ultimately, Dow's current base in Freeport also seemed to play a role in the decision.

Dow Texas Operations in Freeport is Dow’s largest integrated manufacturing site worldwide and the largest single-company chemical complex in North America, the company says.

With 4,200 employees and 3,000 contractors on site daily, Dow Texas Operations currently manufactures 44 percent of Dow products sold in the US and more than 20 percent of Dow products sold globally.

Dow cites favorable US market dynamics “Dow is proud to have been among the first manufacturing companies to declare a comprehensive plan to take advantage of these favorable market dynamics, further enhancing our footprint in the Americas and the profitability of our global businesses while supporting economic revitalization in the communities in which we operate,” said Liveris.

“Dow is proud to have been among the first manufacturing companies to declare a comprehensive plan to take advantage of these favorable market dynamics, further enhancing our footprint in the Americas and the profitability of our global businesses while supporting economic revitalization in the communities in which we operate,” said Liveris.

“Constructing this new ethylene cracker at Dow Texas Operations will create a long-term advantage for our downstream businesses and for our company as a whole, and the benefits will accrue not only to Dow but to the state and national economy."

Dow said the decision to build an ethylene plant in Freeport marks a significant milestone in its strategy to further develop the competitive advantage for its performance plastics, performance materials and advanced materials businesses by expanding access to low-cost natural gas-based feedstocks.

Later this year, Dow is expected to announce details of new ethylene derivative units to be built alongside the cracker. At least one will produce polyethylene (PE). “The outlook for advantaged US natural gas was a significant factor in Dow’s decision to invest $4 billion to grow our overall ethylene and propylene production capabilities in the US Gulf Coast region,” said Jim Fitterling, Dow executive vice president and president of feedstocks and energy and corporate development.

“The outlook for advantaged US natural gas was a significant factor in Dow’s decision to invest $4 billion to grow our overall ethylene and propylene production capabilities in the US Gulf Coast region,” said Jim Fitterling, Dow executive vice president and president of feedstocks and energy and corporate development.

“Today, 70 percent of the company’s global ethylene assets are in regions with cost advantaged feedstocks - and we’ve seen the benefits this advantage provides given oil-based naphtha margin pressure in Europe and Asia,” Fitterling added.

“This plan represents a game-changing move to strengthen the competitiveness of our high-margin, high-growth derivatives businesses as we continue to capture growth in the Americas.”

Other Dow US petrochemical projects

As part of that strategy, Dow is restarting a cracker near Hahnville, Louisiana. Dow said Thursday that process is progressing as planned, and the unit should be on stream at the end of this year.

Earlier this year, Dow said its board of directors had authorized capital to finalize detailed engineering and purchase long lead-time equipment for a world-scale propylene facility, also to be constructed in Freeport.

Earlier this year, Dow said its board of directors had authorized capital to finalize detailed engineering and purchase long lead-time equipment for a world-scale propylene facility, also to be constructed in Freeport.

Basic engineering work for the new on-purpose propylene facility has commenced, and the project is on track to start up production in 2015.

Last December, Dow and Honeywell’s UOP signed a technology licensing agreement, enabling on-purpose propylene production.

Under the terms of that deal, Dow will license UOP's proprietary UOP C3 Oleflex process technology for manufacturing on-purpose propylene from propane, a process known as propane dehydrogenation (PDH).

Dow also signed catalyst supply and performance guarantee agreements with UOP.

All photos courtesy of Dow Chemical. For more on this story, visit Dow's website by clicking here.

Comments