Zeopore and BioBTX boost circular aromatics yield from waste plastics through breakthrough catalyst and process synergies

Zeopore Technologies and BioBTX have jointly demonstrated a major advancement in the conversion of waste plastics and biomass into circular aromatics. By combining BioBTX’s Integrated Cascading Catalytic Pyrolysis (ICCP) technology with Zeopore’s tailored mesoporous zeolite catalysts, the partners achieved up to 100% yield increase in BTX (benzene, toluene, xylene), setting a new benchmark in sustainable chemical recycling.

Driving circular chemistry forward. This collaboration brings together BioBTX’s expertise in process engineering with Zeopore’s mastery of zeolite catalyst design, unlocking synergies that significantly enhance conversion efficiency while reducing emissions.

Niels Schenk, Director of R&D of BioBTX: “Our ICCP process was already designed to maximize circularity and control contamination. By integrating Zeopore’s advanced catalysts, we’ve taken a major step forward in both performance and sustainability. It’s a clear demonstration of how catalyst innovation can accelerate the transition to renewable aromatics.”

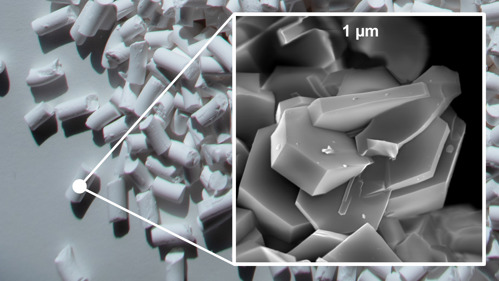

Push in BTX yield and emission reduction. The results show that Zeopore’s gallium-containing mesoporous ZSM-5 catalysts doubled the yield of BTX (benzene, toluene and xylene) aromatics in pilot-scale trials.

The improved porosity and metal distribution of the catalysts enhanced both dehydrogenation and cracking reactions, leading to higher selectivity and less unwanted gas formation.

In addition to boosting yields, the collaboration also achieved a nearly 50% reduction in CO₂-equivalent emissions per unit of aromatics produced, a critical factor in making chemical recycling both economically and environmentally viable.

The science behind the collaboration. This work shows how catalyst accessibility and active site design can directly translate into process efficiency and lower emissions. It’s an excellent example of how material science makes a real impact on the circular economy.

The ICCP technology from BioBTX separates the pyrolysis and catalytic upgrading stages, enabling higher control over reaction conditions and longer catalyst lifetimes.

Next steps: From pilot to commercial scale. Following the success of this joint development, both companies plan to scale up the technology for commercial demonstration. BioBTX will integrate improved catalyst design into its first renewable aromatics plant, while Zeopore continues to expand its catalyst portfolio for waste plastics and biomass upgrading applications.

Kurt Du Mong, CEO of Zeopore “Zeopore and BioBTX share the ambition to accelerate the shift toward a carbon-circular chemical industry, enabling the reuse of end-of-life plastics and bio-based feedstocks as sustainable building blocks for fuels, materials, and chemicals.”

Comments