Digital Exclusive—Valve maintenance: An open and shut case?

D. YOUNG, Celeros Flow Technology (Celeros FT), Aberdeen, Scotland

Valves are essential pieces of flow control equipment used in applications from water treatment and chemical processing to power generation and offshore platforms. They enable the safe and efficient storage, transportation, production and/or processing of gases and liquids at the desired rate, pressure and temperature—often in harsh and remote environments.

Maintaining valves throughout a plant’s lifetime helps to preserve optimal performance, minimize supply disruptions and reduce environmental impacts; however, it can be challenging. Remote locations, extreme operating conditions and the often-aggressive properties of the fluids being transported can pose specific servicing and maintenance challenges (FIG. 1).

FIG. 1. Maintaining valves throughout a plant’s lifetime helps to preserve optimal performance, minimize supply disruptions and reduce environmental impacts.

Warning signs. Valves may remain in one position—either open or closed—for most of their service life. While they may not need to operate frequently, regular maintenance is essential because it is undesirable to discover a valve is not functioning properly at a critical moment. Routine inspection, such as actuator/operator testing (including partial stroke), helps identify early warning signs of valve deterioration. Many issues can be detected early without even opening the valve. However, some signs indicate more serious safety and operational risks that may require urgent intervention. So, what should plant engineers look out for?

Deterioration of consumables. Parts like O-rings become brittle over time, reducing efficacy and leading to breakages. Visual inspection, which can be undertaken without opening the valve, will reveal telltale signs like cracks and discoloration. The part will also feel hard, rather than pliable, to the touch. Other visual indicators may be external leakage through mating components and joints or gaskets that are visibly damaged or protruding from joints, which can indicate overpressure, improper installation or thermal cycling.

Increased energy consumption. Solids accumulate in the bottom of the valve body over time, particularly in dirty services. Left unchecked, this material will adversely affect valve operation, prevent full gate travel and impact the valve’s functional capability. On electrically actuated valves, torque or thrust requirements increase because the actuator must compensate. Left unresolved, sediment build-up results in higher energy costs.

Actuator or handle resistance. Accumulation of solids may also result in excessive force being required to operate the valve manually or via an actuator. Difficulty operating the valve may also indicate internal friction or mechanical failure.

Scratches and gouges. Scoring to the valve stem indicates internal damage to the stem and packing. The yoke must be removed to confirm the cause, which involves some time and cost, but this is preferable to a full rebuild if the damage is not rectified. Full replacement of the valve’s top works to incorporate a two-piece stem rather than a single piece makes it easier to swap out damaged parts and meet actuation requirements. Whether the valve is welded in or buried, this approach can extend valve life without requiring complete replacement.

Leakage. Valves can leak in different ways and for different reasons. Internal leakage (passing) occurs through the valve itself, typically between the seats and the ball, disc or plug. Causes include seat wear, erosion, corrosion or debris lodging between sealing surfaces. Leaking valves are not cheap to repair, particularly if they are sub-surface and/or weld-in valves that must be repaired in situ during planned outages. If a valve is leaking internally (referred to as passing), it will not shut off completely, posing a potential safety risk. Consequences include product losses, product contamination and environmental damage.

External leakage occurs through the gland packing, flanges or body joints. Packing leakage may result from improper installation, thermal cycling, vibration or packing degradation over time. Flange and joint leaks may be caused by gasket failure, bolt loosening or misalignment during assembly. Packing leakages can be temporarily mitigated by injecting packing compound, but this is not a substitute for identifying the cause of the leakage and proper replacement.

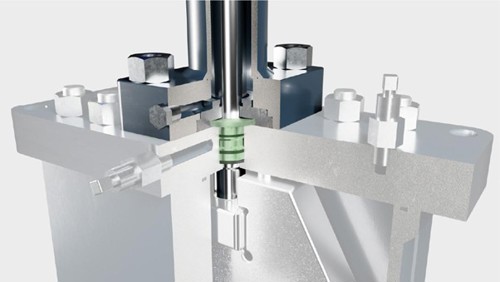

Better leakage prevention. A new way to prevent leaks is the author’s company’s valve packing systema (shown in FIG. 2), developed to reduce fugitive emissions and provide a safe and efficient sealing solution for valves. This valve packing systema uses a spring-loaded mechanism to ensure a tight and robust seal even under extreme conditions, eliminating the need for packing tightness intervention during the seal’s lifetime.

FIG. 2. The author’s company’s valve developed a packing systema to reduce fugitive emissions and provide a safe and efficient sealing solution for valves.

It also accommodates slight misalignments or deformations in the valve stem or body, further helping to prevent leaks and reduce the need for frequent maintenance or repair. Simple to retrofit, the valve packing systema is a good choice for critical valves in remote and inaccessible locations that are not used for extended periods. The packing systema can reduce packing-related maintenance activities and is certified to the International Organization for Standardization (ISO) 15848-1 and ISO 15848-2 fugitive emissions type tests, in addition to adhering to the American Petroleum Institute (API) 6FA and ISO 10497 standards for valve fire tests.

Reactive or corrective maintenance. As every plant engineer knows, an unexpected valve failure or malfunction will occur at some point, despite the best-planned maintenance schedule. This requires reactive/corrective maintenance, which is essentially an unplanned intervention for emergency repairs. The amount of downtime involved largely depends on the availability of qualified personnel and replacement parts. Budget constraints, regulatory requirements, operating environments and personnel availability can all influence maintenance decisions and downtime.

Risk assessments to evaluate the consequences (e.g., safety, environmental, financial) and probability of failure will help determine the appropriate strategies with respect to workforce availability, service contracts and spare parts holding. Decisions should also be supported by historical data, reliability analysis and cost-benefit assessments to guide the choice. The goal is to develop an effective, practical maintenance strategy that ultimately uses preventative maintenance to reduce risks of unplanned failures and ensure that, when they do occur, they can be quickly resolved.

Preventative maintenance. A preventative maintenance regime involving planned, routine actions aids compliance and can prevent valve failures or performance degradation. Preventative maintenance is essential to ensure optimal performance, prevent leaks, minimize downtime and extend the lifespan of valves, but what does best practice look like?

- Regular visual inspections should be undertaken to check valves for signs of wear, corrosion or damage. Any leaks around valve seals, flanges and connections must be addressed promptly. Tighten any loose bolts and replace damaged gaskets as part of any maintenance regime.

- Change out consumables (soft goods) whenever the valve is opened as part of regular maintenance schedules. Ideally, maintenance teams should also replace the valve seat, gate and stem as a precaution at 10-yr intervals for good actor valves. Bad actors require earlier intervention to determine and correct the cause of the problem.

- Regular lubrication of all moving parts is good practice. It reduces friction and ensures smooth operation. Lubrication type and frequency will depend on the valve manufacturer, so always check the guidelines. Grease costs less than loss of production.

- Cleaning valves will remove build-up of dirt and debris, while periodically flushing associated pipelines or vessels will help prevent sediment from accumulating and affecting valve performance.

- Periodic testing of valves under actual operating conditions should be performed at regular intervals (either partial or full stroke). This will ensure that the valves open and close smoothly without sticking or excessive force when required.

- Accurate record keeping and retrieval are key to good valve maintenance. Keep maintenance logs detailing all activities—inspection dates, repairs and replacement parts used, including as-found condition—in an electronic database.

Outsourcing maintenance. Retaining comprehensive valve maintenance resources in-house is not always practical or cost-effective. Outsourcing can provide access to specialized expertise, advanced technologies and a range of services that can enhance safety, efficiency and environmental performance.

Find a partner with extensive experience in valve maintenance management, not just overhaul and repair. They should offer complete lifecycle services, from managing installed equipment to parts supply and engineered upgrades to drive improved reliability and valve life. Check that they can offer customized maintenance solutions tailored to your specific needs, rather than one-size-fits-all. Also, ensure that they are conversant with the relevant accreditations and standards that apply to your processes and equipment, plus your geographic location and regulatory requirements.

The author’s company services and maintains its own-brand and third-party valves via a global network of service centers, ensuring help is always nearby. The company’s valve aftermarket engineers adhere to industry standards such as API 6D, safety regulations and environmental requirements, and hold accreditations to work onshore, offshore and on nuclear facilities. By combining its engineering expertise and materials knowledge, the company can fully engineer new parts for obsolete valves, make lasting repairs, or upgrade valve performance using advanced metals, coatings and design modifications. The company also undertakes inventory management and training programs for customers.

Outsourcing in action. The author’s company successfully resolved a critical valve maintenance challenge for a pipeline operator (FIG. 3), ensuring its project schedule remained on track. The customer faced an unexpected valve failure and required an emergency turnaround to resume operations quickly and prevent significant production losses.

The faulty valve, originally installed in the 1970s, required obsolete spare parts that were no longer available. Although the customer had sourced equivalent components for a newer valve model, these did not fit the existing equipment, and there was insufficient time to design and manufacture new parts from scratch.

FIG. 3. Outsourcing valve maintenance can provide access to specialized expertise, advanced technologies and a range of services that can enhance safety, efficiency and environmental performance.

Leveraging its OEM valve expertise and advanced aftermarket engineering capabilities, the company rapidly engineered and adapted the modern components to fit the legacy valve, restoring its performance. Thanks to this swift and innovative solution, the valve was brought back online within the critical 12-hr maintenance window, helping the customer avoid production losses estimated at $500,000 per day.

Takeaway. Valve maintenance can be a complex yet critical aspect of ensuring the safe, efficient and reliable operation of industrial plants, and should not be overlooked. The challenges are multifaceted, ranging from harsh operating environments and remote locations to the inevitable wear and tear of components over time. The advent of new processes, increasingly stringent environmental regulations and changes in market demand continue to present new maintenance challenges for plant engineers.

By partnering with a lifecycle maintenance partner such as the author’s company, plant operators can ensure their valves remain in optimal condition throughout their lifecycle, reducing risks, enhancing efficiency and achieving long-term operational success.

NOTE

a Celeros Flow Technology’s CFT-Green Valve Packing System

ABOUT THE AUTHOR

DAVID YOUNG is the Valve Aftermarket Development Director at Celeros Flow Technology. His expertise includes the design, manufacture and overhaul of rotating and static equipment, working in both dynamic service environments and original equipment manufacturing. David holds an MEng degree in mechanical engineering and has more than 20 yrs of experience in international technical and managerial roles. He started his career with Celeros FT as an apprentice in the company’s Glasgow factory, which is now the ClydeUnion Pumps brand, rising to be Principal Engineer.

Comments