Digital Exclusive: Mitigating structural resonance in an electric motor support: A field case study

Authors: S. AL DOSSARY and W. KHALAF ALLAH, Saudi Aramco, Dhahran, Saudi Arabia

Rotating equipment operating near structural natural frequencies is prone to resonance, resulting in elevated vibration levels and potential long-term damage. This article discusses a field case involving persistent axial vibration on an electric motor despite acceptable performance during decoupled workshop testing. The discrepancy prompted a full diagnostic investigation, including bump testing, modal analysis and structural reinforcement.

Motor and system description. The equipment in question is a 460-V, 150-horsepower (hp) (112-kW), 4-pole, 60-Hz, 1,800-rpm electric motor operating a lime transfer blower within a petrochemical plant (TABLE 1). Initial data was collected in April 2015, and later follow-ups were conducted throughout 2015 and 2016.

| Speed, rpm | 1,800 |

| Number of poles | 4 |

| Frequency, Hz | 60 |

| Voltage | 460 |

| Kw/hp | 112/150 |

| Current, Amps | 175 |

TABLE 1. Details of the operating electric motor

Initial observations and measurements. Initially, the motor (FIG. 1) exhibited significantly higher axial vibration that fluctuated from 6.6 mm/sec to a peak of 9.8 mm/sec. The vibration spectrum revealed that the operating frequency (30 Hz) was close to the system’s natural frequency (32 Hz), confirming the presence of structural resonance (FIG. 2). The resonance was attributed to insufficient stiffness in the motor support.

FIG. 1. Motor measurement points (click image to enlarge).

FIG. 2. Motor DE axial spectrum indicating dominant 1X rpm (click image to enlarge).

During solo-run testing at the vendor's workshop without the coupling hub, the vibration levels at all points were within acceptable limits (≤ 2 mm/sec peak). TABLE 2 summarizes vibration readings during the solo run.

Onsite measurements and resonance discovery. During the month of August, the motor was taken back to the site to perform the following trial tests:

- Solo run test with a coupling hub

- Solo run test without coupling hub.

The vibrations shown were still on the higher side for both cases. The readings are shown in TABLE 2.

| Measurement points | Measurement point description | July 29th workshop without coupling hub | August 1st onsite with coupling hub | August 17th onsite without coupling hub |

| M1H | Motor outboard, horizontal | 0.6 | 2.3 | 2.5 |

| M1V | Motor outboard Vertical | 0.8 | 0.5 | 0.9 |

| M1A | Motor outboard, axial | 1 | 5.5 | 5.6 |

| M2H | Motor inboard, horizontal | 0.9 | 0.7 | 1.3 |

| M2V | Motor inboard, vertical | 1.2 | 4.5 | 4.4 |

| M2A | Motor inboard, axial | 0.8 | 5.5 | 5.4 |

TABLE 2. Periodic vibration acceptance levels solo run < 2 mm/sec peak.

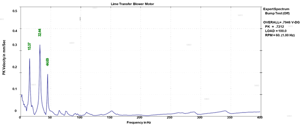

Conducting a bump test. An electric motor bump test is conducted to evaluate the motor's ability to start and run smoothly and to identify any potential issues with the motor's windings, bearings or other internal components. The vibration team performed a bump test on the motor bearings housing and identified a spectrum natural frequency at 32 Hz, which is very close to the running speed of the motor at 1,800 rpm (30 Hz). It is not recommended to run the motor near its natural frequency. Therefore, a minimum of 20% margin should be maintained to run the motor smoothly.

Looking at FIG. 3, it is evident why high vibration exceeding acceptable limits was seen at the site. Vibration measurements are normal during a motor solo run in a workshop—this is because the measured motor bearing housing natural frequency of 32 Hz is close to the motor running speed of 30 Hz, leading to “structural resonance.”

FIG. 3. Bump test at the motor DE axial direction (click image to enlarge).

To avoid such a resonance condition, either changing the mass or changing the structural stiffness is necessary to shift the natural frequency. Such modification will enhance motor rotodynamics (i.e., will create an acceptable resonance margin to run the motor).

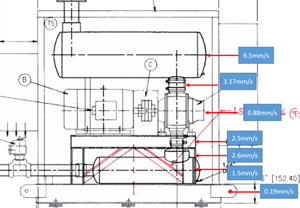

The Equipment Consulting Services Department (ECSD) has requested the end user to take vibration readings on several locations. Measurements are shown in FIG. 4.

FIG. 4. Vibration readings at several locations, as requested by ECSD (click image to enlarge).

Structural modification. To mitigate high vibration, motor supporting structure stiffness was provided by adding two cross beams between the sides of the vertical supports (FIG. 5), as per ECSD recommendations. The motor vender agreed with this recommendation.

FIG. 5. Two cross beams were added between the sides of the vertical supports (click image to enlarge).

Results. After the structural modifications, the vibration levels drastically reduced at the motor DE (from 5.4 mm/sec to 2.5 mm/sec peak) and NDE (5.6 mm/sec to 2.4 mm/sec peak) axial directions (TABLE 3).

| Measurement points | Measurement point description | August 17 onsite without coupling hub | August 23 onsite without coupling hub, after structural modification |

| M1H | Motor outboard horizontal | 2.5 | 2 |

| M1V | Motor outboard vertical | 0.9 | 0.5 |

| M1A | Motor outboard axial | 5.6 | 2.4 |

| M2H | Motor inboard horizontal | 1.3 | 1.5 |

| M2V | Motor inboard Vertical | 4.4 | 1.9 |

| M2A | Motor inboard axial | 5.4 | 2.5 |

TABLE 3. Periodic vibration acceptance levels solo run < 2 mm/sec

Takeaways. The structural modifications resulted in dramatic improvement in the vibration levels. However, present values are at 2.5 mm/sec peak, exceeding end user solo run standard levels of < 2 mm/sec 0-Peak. However, the measured value of 2.5 mm/sec is acceptable by Saudi Aramco standards. It is recommended that the end user measure the vibration of the motor on a monthly basis to ensure motor stability and that the structural modification resolved this issue.

ABOUT THE AUTHORS

Saad Al Dossary is a Senior Engineering Consultant in Saudi Aramco’s ECSD and has more than 25 yrs of experience, specializing in rotating equipment dynamic analysis.

Wesam Khalaf Allah is a Senior Pump Engineer in Saudi Aramco’s ECSD and has more than 13 yrs of experience, specializing in pumps and mechanical seals.

Comments