Digital Feature: WASCO’s Energy Efficiency Roadmap: Leveraging software and AI for operational excellence

M. KHALEEL, El Wastini Petroleum Co. (WASCO), Damietta, Egypt; E. GEBESY, Aspen Technology; and S. SHEIKH, Aspen Technology, UAE

WASCO has introduced an innovative Energy Efficiency Roadmap that uses Aspen HYSYS and artificial intelligence (AI) to address the critical challenges of operational costs and carbon emissions in an liquified petroleum gas (LPG) plant.

This cutting-edge roadmap aims to enhance profitability while promoting sustainability, setting a new benchmark for operation to tradeoff between production and sustainability.

Key components of the Energy Efficiency Roadmap. An implementation of a novel AI-driven approach via AI model builder (AIMB), which utilizes plant data to create a dynamic matrix of unknowns (DMXs). The DMX is a pivotal element that integrates machine-learning (ML) with first principles to disclose critical insights into the relationships between emissions reductions and plant profitability. This hybrid methodology provides a comprehensive understanding of plant operations, enabling precise optimization and decision-making.

Methodology and process. The methodology begins with a systematic analysis of the plant data through advanced ML techniques. This step involves:

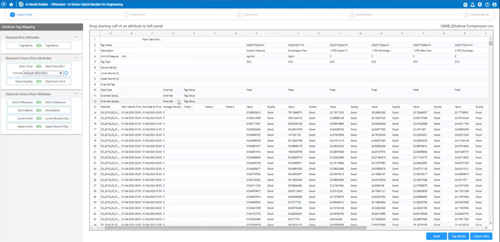

- Data collection: Gathering operational data from the LPG plant, including parameters related to energy consumption, production rates, equipment performance and emissions levels (FIG. 1).

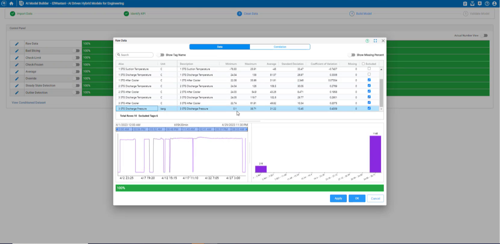

- Data conditioning: Cleaning and preprocessing the data to ensure accuracy and consistency, which is crucial for effective ML analysis (FIG. 2).

- ML application: Applying ML algorithms, namely an artificial neural network (ANN) to analyze the data, identify patterns and establish the DMXs.

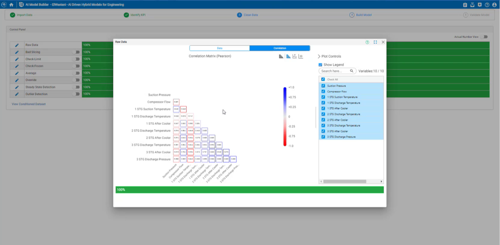

Creation of DMXs. The DMX serves as a sophisticated analytical tool that reveals the complex interdependencies within the plant's operations. It integrates data-driven insights with engineering principles and constraints to provide a holistic view of the plant's performance (FIG. 3).

The key features of the DMX include:

- Insight generation: Identifying critical variables that influence energy efficiency and emissions and understanding their interactions (FIG. 4).

- Predictive modeling: Developing predictive models to forecast the impact of various operational changes on efficiency and emissions.

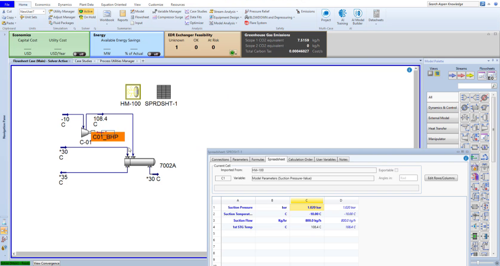

Optimization and target setting. The insights gained from the DMX analysis are instrumental in setting precise targets for WASCO's optimization engine using Aspen’s Sequential Quadratic Programming (SQP). The process involves:

- Target setting: Defining specific efficiency and emissions reduction targets based on the DMX insights.

- Optimization engine: Using Aspen SQP to determine the optimal operating conditions that achieve these targets, ensuring maximum efficiency and profitability.

Digital twin’s operation. The digital twin’s foundation is uniquely positioned around:

- Enhanced decision-making: Providing plant operators with actionable insights that are grounded in both empirical data and engineering theory.

- Improved efficiency: Streamlining energy efficiency strategies by identifying the most impactful operational changes.

Significant outcomes and industry impact. The implementation of WASCO's Energy Efficiency Roadmap has resulted in remarkable results, underscoring the significant impact of AI in the petroleum industry (FIG. 5).

Key outcomes include:

- Reduction in carbon emissions: Achieving substantial decreases in emissions through optimized plant operations.

- Operational cost savings: Lowering operational costs by enhancing energy efficiency and reducing waste.

- Increased profitability: Realizing higher profit margins due to improved operational performance and efficiency (FIG. 6).

Takeaway. WASCO's innovative Energy Efficiency Roadmap, powered by Aspen HYSYS and AI, represents a transformative approach to addressing the dual challenges of operational costs and carbon emissions in the petroleum industry. By leveraging the DMX and integrating ML with first principles, WASCO has set a new standard for energy efficiency and profitability.

The success of this roadmap paves the way for broader adoption of AI-driven methodologies in the industry, promising a future where efficiency and sustainability go hand in hand, ultimately benefiting both the environment and the bottom line.

Comments