Control Station launches System Health Monitoring offering, delivers industry-spanning operational insights

Control Station has launched System Health Monitoring (SHM), a tiered service offering that leverages intelligence captured by the company’s PlantESP Loop Performance Monitoring solution.

The service enables proactive monitoring of PlantESP deployments, facilitating rapid response to system resource issues and guidance for achieving world-class control. Dozens of PlantESP licensees and the associated production facilities enrolled in the service offering prior to the official launch.

Control Station’s PlantESP Loop Performance Monitoring solution capitalizes on a facility’s existing historical process data to assess PID controller performance on a plant- or an enterprise-wide basis. The software uncovers a range of common mechanical, tuning and process interaction issues that undermine productivity and that contribute to unplanned downtime.

PlantESP’s library of metrics automates the identification of controller-related performance issues, and its portfolio of advanced forensic tools simplifies the isolation of root-causes. Historically, monitoring systems like PlantESP could falter due to natural disasters and other unexpected events, and process manufacturers lacked a common method for assessing performance. The introduction of SHM ensures that deployments operate effectively while also providing a benchmark of performance and facilitating the pursuit of world-class production.

“More than verifying a system’s health and providing a prioritized list of tasks, the SHM service benchmarks a plant’s overall effectiveness from a regulatory control perspective,” shared Jonathan Stevens, Control Station’s director of services. “The insights allow customers to see how their plant stacks up against others, and they provide a simple way for licensees to measure the positive impact of each change to their plant’s operation.”

Intelligence derived by PlantESP is transmitted daily via a compact and encrypted machine-readable file. The captured information equips Control Station with timely awareness of:

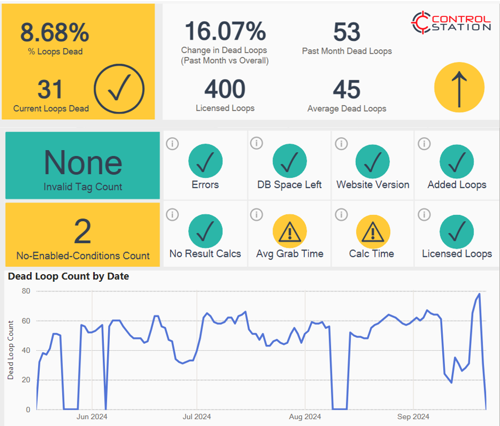

- Server health: Basic evaluations of the system, including verification of server’s status (i.e., on vs. off), calculation engine status and access to required databases.

- Infrastructure analysis: Assessments of system functionality and architecture, including available server and database hard drive space, identification of misconfigured and/or invalid loops and tags, and documentation of “dead loops.”

- Control benchmarking: A singular value for assessing a plant’s regulatory control performance and indicating net changes in performance over time.

Control Station’s SHM offering utilizes a variety of metrics and other intelligence to calculate an Overall Controller Effectiveness™ (OCE) value. OCE is a normalized measure for control loop operations based on the methodology for calculating overall equipment effectiveness. OCE provides a simple, quantitative means for benchmarking various levels of control within a plant. Through receipt of periodic scorecards, subscribers to the SHM service offering can establish plant or even corporate performance standards. Within the tiered service offering, a list of priority recommendations can be provided that aid customers with the targeting of PID-related issues that offer the greatest impact on control and production performance.

“The impact that process engineering and operations teams have on control and plant performance can be hard to measure,” noted Dr. Bob Rice, vice president of engineering at Control Station. “Our SHM service equips those teams with a simple gauge for evaluating their performance. With OCE, they gain a means for tracking progress and perspective on their plant’s positioning relative to the broader manufacturing landscape.”

PlantESP has been successfully deployed at manufacturing facilities both globally and spanning all major segments of the process industries. Information provided for analysis is restricted to a PlantESP server’s available resources and aggregated values of the software’s metric calculations. No proprietary process data is transmitted. All comparisons within SHM assessments are anonymized to ensure that data cannot be traced to any individual source. As of today’s launch, the SHM service has been proven with customers spanning dozens of production facilities and encompassing over 23,000 unique PID control loops.

Comments