MOL Group partners with Evonik, thyssenkrupp for Polyol Project

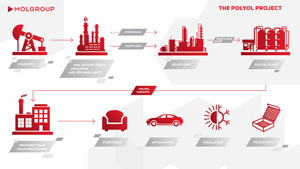

BUDAPEST — Half a year after the announcement of the 2030 strategy, MOL Group has reached an important milestone in its industrial transformational journey. The license agreements signed with Evonik and thyssenkrupp, will enable MOL to produce propylene oxide, a key component for the production of polyether polyols. MOL intends to become a significant producer of polyether polyols, high-value intermediates for products applied in the automotive, packaging and furniture industries.

MOL Group has entered into key contracts related to core technologies of the Polyol Project, which was announced in 2016 as part of the first investment cycle of the MOL 2030 long-term strategy. The contracts concern the purchase of technology licenses and process design packages for the so called HPPO (hydrogen peroxide to propylene oxide) technology of propylene oxide production.

The licensor of the hydrogen-peroxide unit for captive use is Evonik, while a consortium formed by Evonik and thyssenkrupp Industrial Solutions licenses the propylene oxide unit. The contracts also contain binding offers and pre-agreements regarding the later engineering and execution phases of the HPPO units by thyssenkrupp and the purchase of proprietary catalysts from Evonik.

In addition, MOL Group has selected Fluor as Project Management Consultant (PMC) for the front-end engineering design and engineering, procurement and construction phases of the project. MOL Group is in the final stages of selecting the licensor for polyether polyol technology as well as the contractor for the engineering of the utilities and other facilities.

These agreements represent the first milestone in the execution of the MOL 2030 long-term strategy, which earmarked around $1.9 B in investments for transformational projects in the area of chemicals and petrochemicals for the period of 2017–2021. The industrial complex, which will be built in Hungary, will be the single largest organic investment project of MOL Group in 2017-21. Propylene oxide based polyols serve as raw materials for polyurethane foams, which are widely applied in the automotive, construction, packaging and furniture industries.

The planned new industrial complex consists of the HPPO plants having 200 kt/year propylene oxide production capacity, several production lines for polyether polyols, utilities and other infrastructural investments.

Comments