Ceramic-based conversion produces clean, low cost chemicals from natural gas.

A team of scientists from CoorsTek Membrane Sciences, the University of Oslo (Norway), and the Instituto de Tecnología Química (Spain) has developed a new process to use natural gas as raw material for aromatic chemicals. The process uses a ceramic membrane to make the direct, non-oxidative conversion of gas to liquids possible for the first time — reducing cost, eliminating multiple process steps, and avoiding any carbon dioxide (CO2) emissions. The resulting aromatic precursors are source chemicals for insulation materials, plastics, textiles, and jet fuel, among other valuable products.

Direct activation of methane, the main component of biogas and natural gas, has been a key goal of the hydrocarbon research community for decades.

“Consider the scale of the oil, gas, and petrochemicals industry today”, says Dr. Jose Serra, Professor with Instituto de Tecnología Química (ITQ) in Valencia, Spain, a leading research lab for hydrocarbon catalysis and a co-author of the report in Science. “With new ceramic membrane reactors to make fuels and chemicals from natural gas instead of crude oil, the whole hydrocarbon value chain can become significantly less expensive, cleaner, and leaner.”

“By using a ceramic membrane that simultaneously removes hydrogen and injects oxygen, we have been able to make liquid hydrocarbons directly from methane in a one-step process. As a bonus, the process also generates a high-purity hydrogen stream as a byproduct,” explains Professor Serra. “At a macro level it is really very simple – inexpensive, abundant gas in and valuable liquid out through a clean, inexpensive process. At a nanochemistry level, however, where molecules interact with catalyst and membrane at a temperature around 700° C, there were many factors to engineer and control in order to render just the specific valuable molecules needed to make the new process work.”

Methane constitutes a large fraction of the world’s hydrocarbon resource, but much of this resource is stranded without economically viable paths to market. Even when available for industrial conversions, the high stability of the methane molecule leads to energy losses associated with multi-stage processing in large chemical plants which use oxygen or steam to activate the methane in what is known as synthesis gas processing.

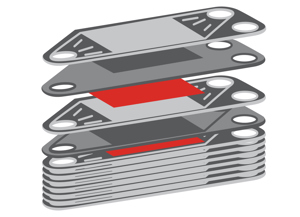

Temperature and pressure have historically been the main parameters chemists and engineers can work with to control reactions. Catalysts can improve speed and selectivity, without promoting reactions beyond their chemical equilibrium limit. Integrating a ceramic ion-conducting membrane into the reactor enables an increase in the productivity of industrially appealing processes which are otherwise impractical due to strong thermodynamic constraints.

The ceramic membranes are made from abundant materials like barium and zirconium found within large sand deposits, with the addition of thin electro-catalytic layers of plentiful metals like nickel and copper.

“With high-volume manufacturing, we can make membrane reactors from active ceramics that are cost competitive with conventional catalytic reactors for gas processing,” said Per Vestre, Managing Director at CoorsTek Membrane Sciences. “While the reactor costs will be similar, the results enabled by this new process have the potential to significantly improve both the financial and environmental costs of chemical production, a development CoorsTek believes will make the world measurably better.”

“By using a ceramic membrane that simultaneously removes hydrogen and injects oxygen, we have been able to make liquid hydrocarbons directly from methane in a one-step process."

Comments